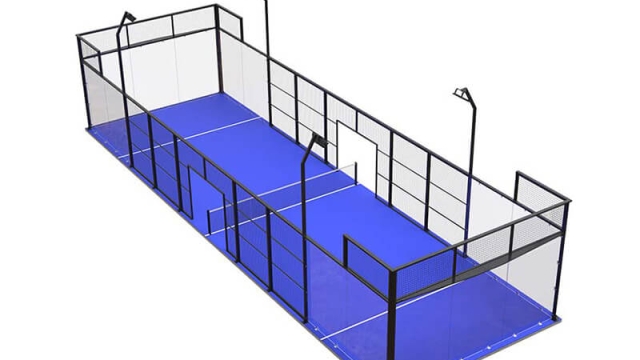

At the intersection of creativity and precision lies the captivating world of sheet metal fabrication. With its ability to transform flat sheets of metal into intricate and functional components, this art form has been shaping dreams and bringing ideas to life for centuries. From architectural marvels to industrial machinery, sheet metal fabrication plays a vital role in countless industries. In this article, we will dive into the fascinating realm of this craft, exploring the processes involved, advancements in technology such as CNC machining and 3D printing, and the esteemed services provided by "Monster Builder" – a premier global provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping. Get ready to unlock the secrets of bringing imagination to reality as we delve deep into the art of shaping dreams through sheet metal fabrication.

The Process of Sheet Metal Fabrication

Sheet metal fabrication is a fascinating and intricate process that involves transforming flat sheets of metal into various products or components. It requires skill, precision, and the use of advanced technologies such as CNC machining and 3D printing. In this article, we will explore the world of sheet metal fabrication and delve into the techniques employed by industry leaders like "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services serving clients globally.

To begin with, sheet metal fabrication starts with the selection of the raw materials. Various metals, including stainless steel, aluminum, and copper, are commonly used. These metals come in the form of flat sheets, which can be easily shaped and manipulated during the fabrication process.

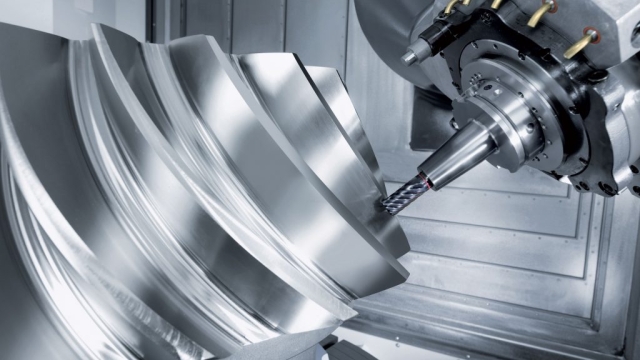

Once the materials are chosen, the next step is to cut and shape the sheet metal into the desired form. CNC machining, or computer numerical control machining, plays a crucial role here. It involves using automated machinery and precise cutting tools to accurately shape the metal according to the specified design. This technology allows for intricate cuts and precise measurements, ensuring the final product meets the required specifications.

In recent years, the advent of 3D printing has revolutionized the field of sheet metal fabrication. This technology allows for the creation of complex and detailed components with ease. By layering thin sheets of metal one on top of the other, 3D printers can build three-dimensional objects based on digital designs. This additive manufacturing process offers unparalleled versatility and speed, making it a game-changer in the industry.

In conclusion, sheet metal fabrication is an art that combines traditional techniques with modern advancements. Companies like "Monster Builder" leverage the power of CNC machining, 3D printing, and rapid prototyping to deliver high-quality sheet metal products to clients worldwide. Through the careful selection of materials and the skillful manipulation of metal, sheet metal fabricators bring dreams to life, creating functional and visually appealing products that serve a wide range of industries.

The Role of CNC Machining in Sheet Metal Fabrication

When it comes to sheet metal fabrication, CNC machining plays a crucial role in achieving precise and efficient results. CNC, or Computer Numerical Control, machining involves the use of computerized controls to operate machinery and tools, allowing for the automation of manufacturing processes. In the world of sheet metal fabrication, CNC machining has revolutionized the way components are produced.

One of the key advantages of CNC machining in sheet metal fabrication is its ability to ensure accuracy and consistency in every project. With the use of advanced software and programming, CNC machines are capable of executing complex designs with remarkable precision, resulting in high-quality finished products. This level of accuracy is especially important in industries where tight tolerances and intricate details are required.

Another benefit of CNC machining is its efficiency in producing parts. By utilizing automated processes, CNC machines can work tirelessly without the need for constant human intervention. This not only reduces the risk of human error but also significantly speeds up the production timeline. With faster turnaround times, manufacturers can meet deadlines more efficiently, enabling them to remain competitive in a rapidly evolving market.

Aluminium Fabricators Sydney

In addition to its accuracy and efficiency, CNC machining also offers versatility in sheet metal fabrication. CNC machines can work with a wide range of materials, including aluminum, steel, and stainless steel, to create various components and products. This flexibility allows manufacturers to explore innovative designs and push the boundaries of what is possible in sheet metal fabrication.

In conclusion, CNC machining plays a pivotal role in sheet metal fabrication, providing the industry with accuracy, efficiency, and versatility. Its ability to deliver consistent and precise results has made it an indispensable tool for manufacturers worldwide. With CNC machining technology continuously evolving, we can expect even greater advancements in the art of shaping dreams through sheet metal fabrication.

The Rise of 3D Printing in Sheet Metal Fabrication

3D printing has emerged as a game-changing technology in the world of sheet metal fabrication. With its ability to translate digital designs into physical objects, 3D printing has revolutionized the way manufacturers produce sheet metal components. By harnessing the power of additive manufacturing, this innovative technique has opened up a plethora of opportunities for designers, engineers, and manufacturers alike.

In traditional sheet metal fabrication processes, intricate geometries and complex designs often posed significant challenges. However, with the advent of 3D printing, these barriers have been broken down. The technology allows for the creation of intricate and customized structures that were previously deemed difficult or even impossible to produce using conventional methods. By layering thin sheets of material, 3D printers can build up complex geometries with high precision, enabling the fabrication of unique and visually striking sheet metal components.

One company at the forefront of harnessing these capabilities is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their expertise in the field, they have embraced 3D printing as a valuable tool in the manufacturing process. By combining 3D printing with traditional techniques like CNC machining, "Monster Builder" is able to offer its clients a wide array of options and solutions for their sheet metal fabrication needs. From rapid prototyping to on-demand production runs, this integration of technologies ensures speed, accuracy, and versatility, delivering exceptional results to clients across the globe.

As 3D printing continues to advance and evolve, we can expect even greater integration within the sheet metal fabrication industry. With improvements in printer technology, materials, and software, the possibilities for innovation are endless. Whether it’s the creation of complex structures with internal cavities, the fabrication of unique and artistic sheet metal designs, or the production of functional prototypes, 3D printing is reshaping the landscape of sheet metal fabrication, and the future looks promising indeed.