In the fast-paced world of warehousing and logistics, efficiency is key to maximizing productivity. One essential tool in this environment is the forklift, a versatile machine that helps move heavy loads with ease. While forklifts are invaluable on their own, the addition of fork lift extensions can significantly enhance their capabilities, allowing operators to handle larger and bulkier items safely and effectively.

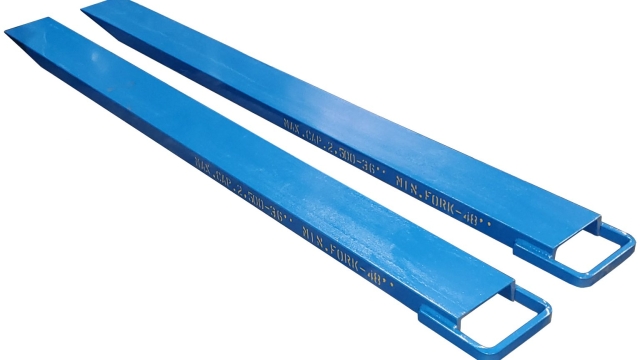

Fork lift extensions are attachments that increase the length of the forklift’s forks, empowering users to lift wider loads without compromising stability. This not only streamlines operations but also helps prevent damage to goods and decreases the risk of accidents in the workplace. As businesses strive to do more with less, understanding how to utilize these extensions can be a game changer in optimizing the performance of your forklift fleet.

Understanding Forklift Extensions

Forklift extensions are specialized attachments designed to increase the length of a forklift’s forks. These extensions provide additional reach and allow forklift operators to handle larger or longer loads that would otherwise be difficult to manage. By extending the forks, operators can efficiently lift and transport materials that exceed the standard fork length, improving overall productivity in the warehouse or job site.

When using forklift extensions, it is crucial to ensure they are properly fitted and secured to the existing forks. This attachment should only be used within the manufacturer’s guidelines to maintain safety during operations. It is important to note that using extensions can alter the forklift’s load capacity, so operators must be mindful of weight limits to prevent accidents or equipment damage.

Forklift Parts

Proper training and familiarity with forklift extensions are essential for operators. Understanding the attachment’s specifications and how it affects the forklift’s stability and maneuverability can significantly enhance safety and efficiency. Freight handlers and warehouse managers should prioritize proper training to maximize the benefits of forklift extensions while minimizing risks.

Benefits of Using Extensions

One of the primary benefits of using fork lift extensions is increased versatility. Standard forklift forks may limit the range of materials and loads that can be handled effectively. By incorporating extensions, operators can comfortably manage larger items without compromising safety or efficiency. This flexibility allows businesses to diversify their operations and handle various types of goods, leading to improved productivity.

Another significant advantage is the enhanced load capacity that extensions provide. Fork lift extensions can distribute weight more evenly across the forks, allowing for the transportation of heavier and bulkier items. This capability is especially beneficial in warehouses and distribution centers, where heavy pallets or large containers are common. By maximizing the lift’s potential, businesses can optimize their material handling processes and reduce time spent on loading and unloading.

Finally, using fork lift extensions contributes to better safety practices in the workplace. When loads are too large for standard forks, workers may resort to risky maneuvers that can lead to accidents or injuries. Extensions allow for safer handling of oversized loads, minimizing the risk of tipping or dropping items. By investing in these extensions, companies not only protect their employees but also reduce the likelihood of damage to goods and equipment, fostering a safer work environment overall.

Safety Considerations

When using fork lift extensions, safety should always be a top priority. These extensions can significantly increase the length of the fork, which can affect the stability and balance of the lift truck. Operators must ensure that the load is well within the capacity limits of the forklift to prevent tipping or accidents. It is essential to regularly inspect the extensions for any signs of wear or damage before use. A thorough pre-operation check can help identify potential issues that may compromise safety.

Proper training for operators is crucial when dealing with fork lift extensions. Operators should be familiar with the specific attachment and its operational guidelines. This includes understanding how the extensions impact the machine’s center of gravity and responsiveness. Ensuring that all personnel involved in the operation are trained and aware of proper handling techniques can drastically reduce the risk of accidents and injuries in the workplace.

In addition to operator training, it is important to maintain clear communication on the job site. When using fork lift extensions, the visibility and control of the load can be altered, leading to potential hazards. Establishing designated pathways and signaling systems can help coordinate movements and keep everyone safe. Regular safety meetings and reminders about best practices can reinforce a culture of safety that is essential for any operation utilizing fork lift extensions.

Choosing the Right Extension

When selecting the right forklift extension, it is essential to consider the specific load requirements of your operations. The capacity of the forklift, along with the nature of the materials being lifted, plays a crucial role. Extensions come in various lengths and widths, so ensuring the right match for both the forklift and the load will help to maximize safety and efficiency.

Another important factor is the type of extension needed for your tasks. Some extensions are designed for specific applications, such as handling long or oversized loads, while others are versatile enough to handle a variety of objects. Assessing the handling needs and any unique challenges your operations might face can help narrow down the options to find the most suitable extensions.

Lastly, pay attention to the quality and durability of the extensions you are considering. Look for reputable manufacturers that offer high-quality materials and robust construction. Investing in reliable forklift extensions will not only enhance performance but also contribute to the longevity of your equipment and minimize safety risks in your workplace.