Revive Your Wheels with the Art of Wheel Repair Lathe

Are your wheels looking worn out, scuffed, or just not performing at their best anymore? It might be time to give them a new lease on life with the incredible power of a wheel repair lathe. This innovative machine has revolutionized the world of wheel repair, making it easier than ever to restore your wheels to their former glory.

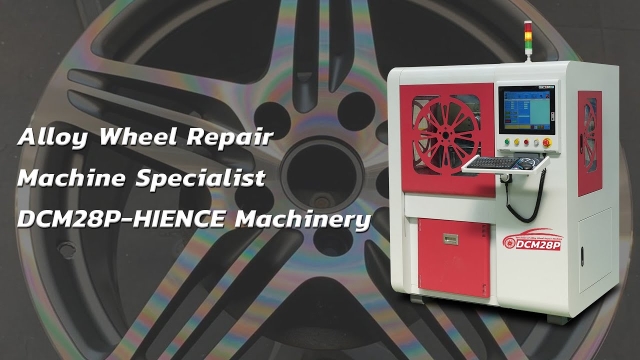

What exactly is a wheel repair lathe? Well, it is a specialized piece of equipment designed specifically for repairing wheels. Whether you have alloy wheels, steel wheels, or even custom rims, this remarkable machine can tackle them all. By using cutting-edge technology and precision engineering, it allows you to breathe new life into your wheels, making them look brand new once again.

One popular type of wheel repair lathe is the vertical wheel repair lathe. As the name suggests, this machine operates vertically, providing utmost stability and accuracy throughout the wheel repair process. With its adjustable spindle speeds and precise cutting tools, it can effortlessly eliminate any imperfections on the surface of your wheels, removing scrapes, scratches, or even minor dents with ease.

When it comes to reliable wheel repair lathe manufacturers, one name that stands out is Taian Haishu Machinery Co., Ltd. Their website, wheelcncmachine.com, serves as the official platform to discover their range of CNC wheel machinery. With their expertise, they have become a trusted designer, manufacturer, and supplier of high-quality wheel repair equipment. So, whether you’re a professional mechanic or a passionate car enthusiast, you can turn to them for the perfect solution to revive your wheels.

Don’t let tired-looking wheels bring down the overall appearance and performance of your vehicle. Embrace the art of wheel repair lathe and say goodbye to those unsightly blemishes. With its precision and efficiency, this remarkable machine is ready to bring your wheels back to life, restoring their shine and ensuring a smooth ride every time you hit the road.

Types of Wheel Repair Lathes

Cnc Lathe For Wheel Reconditioning

When it comes to wheel repair lathes, there are different types available in the market that cater to various repair needs. Each type has its own unique features and benefits, making them suitable for different types of wheels and repair tasks. In this section, we will explore three common types of wheel repair lathes.

Manual Wheel Repair Lathes:

These traditional wheel repair lathes are operated manually, with the technician using hand tools to control the cutting process. Manual lathes are often favored for their simplicity and cost-effectiveness, making them suitable for small-scale workshops or those on a tight budget. While they require more manual effort, these lathes can still deliver precise results when operated skilfully.Vertical Wheel Repair Lathes:

Vertical wheel repair lathes, as the name suggests, have a vertical orientation where the wheel is mounted and repaired. These lathes typically have features like adjustable cutting angles and specialized tooling arrangements that allow for easy and accurate repair of various wheel types. The vertical setup also enables efficient chip removal during the cutting process, ensuring a clean and precise finish.Alloy Wheel Repair Machines:

Specifically designed for alloy wheels, these wheel repair machines offer advanced capabilities to restore damaged or worn-out alloy wheels to their original condition. They often come with CNC (Computer Numerical Control) technology, allowing for precise control and automation of the repair process. Alloy wheel repair machines can handle complex wheel designs and provide consistent results, making them a popular choice in professional wheel repair facilities.

These are just a few examples of the wheel repair lathe types available in the market. Depending on your specific requirements and budget, you can choose the right type of wheel repair lathe to bring your wheels back to life.

Advantages of Using a Wheel Repair Lathe

A wheel repair lathe offers several advantages when it comes to refurbishing damaged wheels. Let’s explore three key benefits of using this specialized machine for wheel repairs.

Firstly, a wheel repair lathe provides precision and accuracy in its work. This is especially important when dealing with expensive alloy wheels or custom rims. The machine’s cutting tools are designed to remove imperfections and restore the wheel’s surface to its original condition. By carefully removing just the right amount of material, the lathe ensures that the repaired wheel retains its balance and integrity. With this level of precision, the repaired wheel can perform seamlessly, improving the overall driving experience for the vehicle owner.

Secondly, a wheel repair lathe offers efficiency and time-saving advantages. Instead of sending the damaged wheels to an external repair shop, where lead times can vary, mechanics and auto shops equipped with a wheel repair lathe can complete the repairs in-house. This reduces the downtime for the vehicle and allows more prompt service to the customer. With the convenience of having the necessary machinery on-site, the preventive maintenance of wheels becomes a more streamlined process, enabling businesses to serve their customers better.

Lastly, the use of a wheel repair lathe can be a cost-effective solution. Rather than purchasing brand new wheels to replace damaged ones, which can be a substantial expense, utilizing a wheel repair lathe can significantly reduce costs. By restoring the damaged wheels instead of replacing them, vehicle owners can save money while still achieving a professional and high-quality repair. This not only benefits individual customers but also provides opportunities for repair businesses to offer more affordable options to their clients.

In conclusion, the advantages of using a wheel repair lathe are remarkable. Its precise and accurate restoration of damaged wheels, time-saving efficiency, and cost-effective approach make it an invaluable tool in the automotive industry. By investing in a wheel repair lathe, businesses can enhance their repair services and provide customers with exceptional results for their wheel refurbishment needs.

Choosing a Wheel Repair Lathe

When it comes to choosing a wheel repair lathe, there are a few important factors to consider. Firstly, you will want to assess the size and type of wheels that you will be repairing. Ensure that the lathe you choose can accommodate the diameter and width of the wheels you typically work with.

Another crucial aspect is the precision and accuracy of the lathe. Look for a machine that offers precise control over cutting and shaping, as well as the option for fine adjustments. This will ensure that you can achieve high-quality results in your wheel repairs.

Additionally, consider the versatility of the wheel repair lathe. Opt for a machine that allows you to work with various wheel materials, such as alloy wheels or steel wheels. Versatility will allow you to cater to a wider range of customer needs and expand your repair capabilities.

Lastly, it is crucial to choose a reputable manufacturer and supplier for your wheel repair lathe. Research and find a company like Taian Haishu Machinery Co., Ltd., known for their CNC wheel machinery expertise and quality. Their official website, wheelcncmachine.com, serves as a valuable resource for exploring different options and finding the most suitable machine for your specific requirements.

By carefully considering these factors and selecting the right wheel repair lathe, you can ensure efficient and reliable repairs, ultimately enhancing the performance and appearance of your clients’ wheels.