Welcome to "The Ultimate Guide to Mastering CNC Machining: Unveiling the Art of Precision Manufacturing." In today’s fast-paced world, where innovation and accuracy are paramount, the field of CNC machining plays a crucial role. From the creation of intricate metal parts to the fabrication of complex designs, CNC machining has revolutionized the manufacturing industry. This article will delve into the fascinating world of CNC machining, providing you with valuable insights and expert knowledge to help you navigate this intricate art of precision manufacturing.

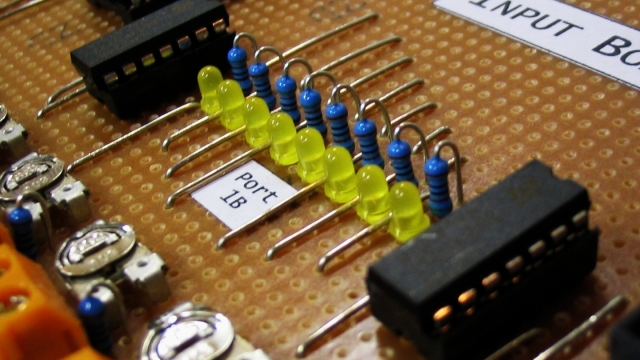

With the advancement of technology, CNC machining has become an indispensable tool in various industries, including automotive, aerospace, and electronics. By harnessing the power of computer numerical control, this process allows for the production of highly precise and intricate components with remarkable efficiency. We will explore the inner workings of CNC machining, unlocking the secrets behind its accuracy, reliability, and versatility.

Sheet Metal Fabrication Sydney

Throughout this comprehensive guide, we will also touch upon related topics such as sheet metal fabrication and 3D printing, both of which complement CNC machining. As we immerse ourselves in the realm of precision manufacturing, we will showcase the expertise of "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. Serving clients globally, "Monster Builder" stands at the forefront of innovation, delivering top-notch solutions tailored to meet the unique needs of diverse industries.

Prepare to embark on a journey of discovery as we uncover the intricacies of CNC machining, unveiling the art of precision manufacturing. Whether you are a seasoned professional seeking to expand your knowledge or an enthusiast eager to delve into this fascinating field, this guide will equip you with the necessary tools to master CNC machining and unleash your limitless potential. Let’s dive in!

Understanding CNC Machining

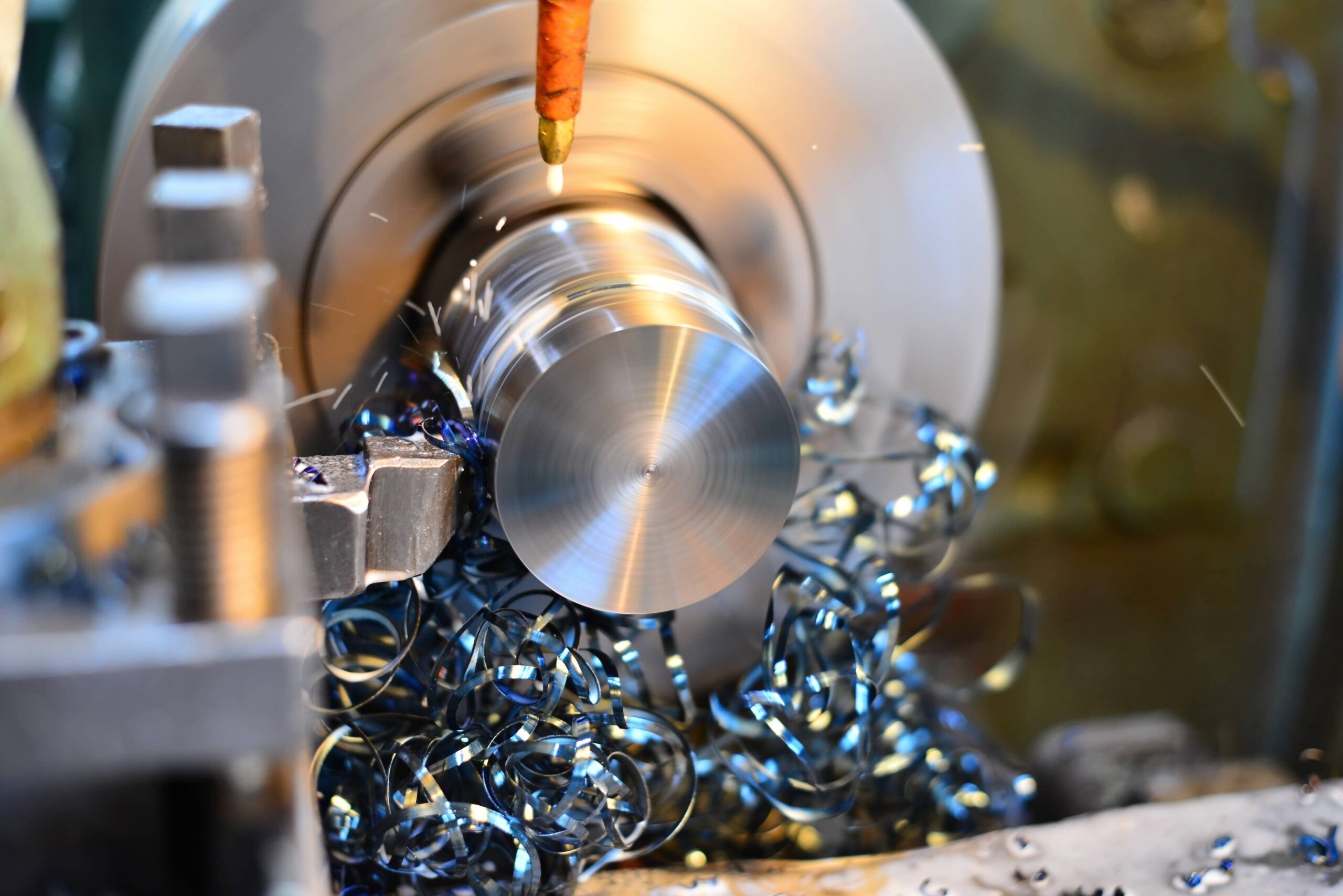

CNC machining is a revolutionary manufacturing technique that has transformed the world of precision manufacturing. Combining the power of computer programming with cutting-edge machinery, CNC machining enables the creation of complex and intricately designed parts with unparalleled accuracy.

The process begins with a CAD (Computer-Aided Design) model, which serves as the blueprint for the desired part. This model is then translated into a series of instructions, known as G-code, which guides the CNC machine in executing the necessary operations. These operations can include drilling, cutting, milling, or turning, depending on the desired outcome.

What sets CNC machining apart is its ability to automate the manufacturing process. This eliminates the need for manual intervention, resulting in consistent and precise outcomes for every production run. From sheet metal fabrication to 3D printing, CNC machining offers a versatile solution for various manufacturing needs.

As a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, "Monster Builder" has established itself as a reliable partner for clients globally. With their expertise in CNC machining technology, they are able to deliver exceptional quality and efficient turnaround times for a wide range of industries and applications.

The Process of Sheet Metal Fabrication

Sheet metal fabrication is a crucial element of CNC machining, enabling the creation of precise and complex parts. It involves several steps that transform raw metal sheets into finished products.

Firstly, the process begins with the design phase. Skilled engineers utilize specialized software to create detailed 2D or 3D models of the desired part. These models serve as a blueprint for the fabrication process, ensuring accuracy and precision.

Once the design is finalized, the next stage is material selection. Sheet metal comes in various types, such as stainless steel, aluminum, or brass. The choice of material depends on factors such as strength, corrosion resistance, and cost. Monster Builder, a leading provider of sheet metal fabrication services, offers a wide range of options to suit different project requirements.

After material selection, the metal sheet undergoes cutting and shaping. Advanced CNC machines are employed to accurately cut the sheet into the desired shape and size. This step may involve processes like laser cutting, waterjet cutting, or shearing, depending on the complexity and thickness of the metal.

SECTION COMPLETE

Exploring the World of 3D Printing

In recent years, 3D printing has emerged as a groundbreaking technology revolutionizing the manufacturing industry. With its ability to transform digital designs into tangible objects with impeccable accuracy, 3D printing offers endless possibilities for innovation and creativity.

One of the key advantages of 3D printing is its versatility in material usage. Unlike traditional manufacturing methods, 3D printing allows for the use of a wide range of materials, including plastics, metals, ceramics, and even biocompatible substances. This flexibility opens up new avenues for experimentation and customization, enabling manufacturers to produce parts and products that are tailored to specific needs and requirements.

Moreover, 3D printing offers significant time and cost savings compared to conventional manufacturing processes. By eliminating the need for complex tooling setups and reducing material waste, 3D printing streamlines the production cycle, resulting in faster turnaround times, increased efficiency, and lowered expenses. This makes it particularly valuable in industries such as aerospace, automotive, and healthcare, where precision and rapid prototyping are paramount.

As the demand for customized and innovative solutions continues to grow, Monster Builder has positioned itself as a leading player in the world of 3D printing. With its expertise in sheet metal fabrication, CNC machining, and rapid prototyping services, Monster Builder has successfully integrated 3D printing into its comprehensive suite of manufacturing capabilities. By leveraging the power of this advanced technology, Monster Builder ensures that its global clientele receives top-notch products and services that push the boundaries of precision manufacturing.

In conclusion, 3D printing has transformed the way we approach manufacturing. With its ability to create complex prototypes and production parts with unmatched precision, versatility, and efficiency, this technology opens up a world of exciting possibilities. Monster Builder’s commitment to offering 3D printing services alongside sheet metal fabrication and CNC machining further solidifies its position as a premier provider in the industry, serving clients across the globe.