Actuated valves and controls play a crucial role in the effective operation of various industrial, institutional, and government facilities. Established in 1991, Valworx stands out as a trusted supplier of these essential components, holding an ISO 9001 certification to ensure quality and reliability. By offering a wide range of automated valve assemblies that are built, tested, and shipped the same day, Valworx demonstrates a commitment to efficiency that resonates with the markets it serves. With hundreds of options available, Valworx empowers industries to optimize their systems with precision and ease, enabling smoother operations and improved control.

Automated valve assemblies

Valworx’s Product Range

Valworx, an industry leader in actuated valves and controls, boasts a wide selection of automated valve assemblies designed to meet diverse industrial needs. With over 30 years of experience and ISO 9001 certification, Valworx is dedicated to delivering high-quality products that ensure efficient operation and longevity.

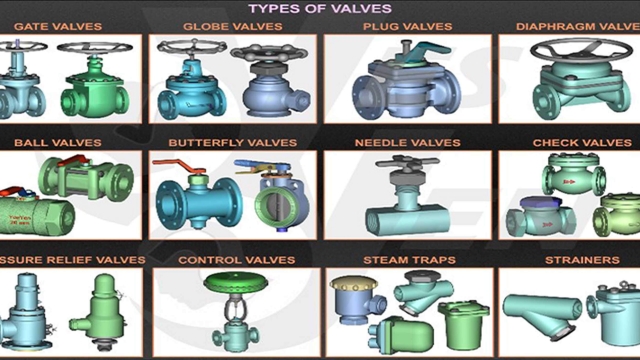

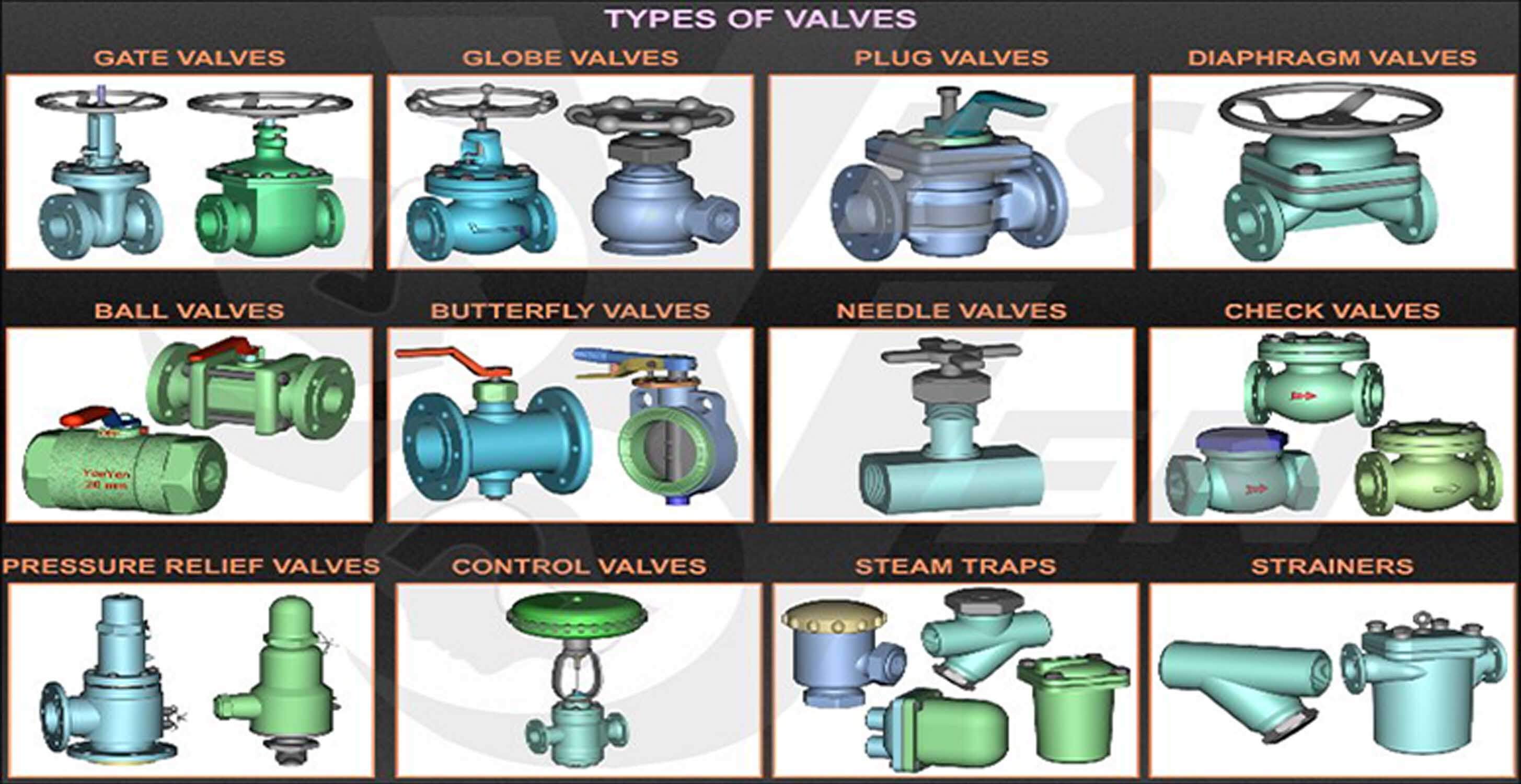

The product range offered by Valworx includes a variety of actuated ball valves, butterfly valves, and solenoid valves, among others. Each valve assembly is meticulously built and tested by expert technicians to guarantee top-notch performance and reliability in demanding environments.

Whether for industrial, institutional, or government applications, Valworx provides tailored solutions that cater to different specifications and requirements. Customers can rely on Valworx for prompt delivery of quality actuated valves that are ready for seamless integration into their control systems.

Benefits of Actuated Valves

Actuated valves provide precise control over fluid flow, enhancing operational efficiency and reducing energy costs. With Valworx’s wide range of automated valve assemblies, industries can easily integrate these systems into their existing setups. The quick turnaround time ensures minimal downtime during installation and maintenance, maximizing productivity.

Furthermore, actuated valves offer reliable performance, aiding in process optimization and risk mitigation. Valworx’s ISO 9001 certification guarantees high-quality products that adhere to industry standards, giving users peace of mind knowing they are investing in durable and safe solutions. The ability to automate valve operations leads to consistent and accurate flow regulation, contributing to overall system reliability.

In addition, the convenience of same-day shipping from Valworx ensures that businesses can swiftly acquire the necessary actuated valves and controls for their specific needs. This agility in supply chain management streamlines procurement processes and enables swift responses to operational demands, ultimately fostering a more agile and responsive organization.

Applications of Actuated Valves

Actuated valves play a crucial role in various industries, providing efficient control and automation for a wide range of applications. In the oil and gas sector, these valves are utilized for precise regulation of flow, pressure, and temperature in pipelines and processing facilities. This ensures optimal operation and safety, especially in critical processes where accuracy is paramount.

The water and wastewater industry also benefits significantly from actuated valves, where they are essential for controlling the flow of liquids in treatment plants, pumping stations, and distribution systems. This helps in maintaining water quality, managing resources effectively, and preventing issues such as overflow or contamination. Actuated valves enhance operational efficiency and contribute to sustainable water management practices.

Moreover, in the manufacturing sector, actuated valves are integral components in automated production lines and machinery. By enabling remote operation and precise adjustment of fluid flow, these valves facilitate seamless industrial processes, improve product quality, and enhance overall productivity. Their reliability and performance make them indispensable for a wide range of manufacturing applications.